As we quickly approach the one year anniversary of this illustrious website, I am reminded of how I came to be involved with this group of interesting, diverse, unusual, but eminently talented group of writers and car enthusiasts. It all started a few years ago when David Tracy was still working at that German Lighting Site and wrote a detailed engineering review of the then-new Ford Bronco. He compared FoMoCo’s new off-road steed to a Jeep Wrangler and noted, in particular, the differences in the front suspension designs. I posted a comment to that article explaining why the different suspension designs affected the way the vehicles behaved off-road, and it turned into a bit of a dissertation to be frank. I’m sure most readers got about 10% through my reply and rolled their eyes or fell asleep, but David thought enough of it to call me a few years later and ask if I would want to join a new website he and Jason were starting. The rest as they say is history.

Here’s my original comment, which you absolutely don’t have to read all the way through:

Of course, the comment section of a car website is a poor place to discuss engineering principles so today we’re going to revisit my comment and talk about why the differences between a solid axle (like the one at the front and rear of the Jeep and rear of the Bronco) and independent suspension (like the one in the front of the Bronco) are so significant when it comes to off-road and on-road driving performance.

Roll Centers Are The Key

As I stated a few years ago, when we talk about why solid axles “flow” over rocks and independent suspensions tend to seem a little more clumsy, it all comes down to roll centers (which I explain here at this link), and in particular, the height of the front suspension roll centers. The roll center is an imaginary point defined by the geometry of the suspension, and it, simplistically speaking, represents the point about which the body will rotate as it rolls side to side in a turn. Every suspension design has a roll center, and when you draw a line from the front suspension roll center to the rear suspension roll center you get the roll axis that the body rolls around. It’s kind of like the way a door pivots around a line going through the centers of the hinges. The roll axis acts like a hinge that the body rolls, or pivots, around in a turn.

Let’s see what happens when a car is in a left-hand turn.

We want the car to go around the bend, but the car actually just wants to go straight. This is because of something pesky called Newton’s First Law, which states that an object in motion wants to remain in motion along a straight line unless subjected to some external force. In the case of our car, it will stay moving along a straight line unless we push on it with something. That “something” is the tires (Technically, it’s the ground pushing the tires, but those tires are pushing the chassis towards the inside of the turn). When we steer the car, the friction between the tires and the road produces a force pushing sideways on the car, forcing it to move away from the straight line it really wants to follow. Now let’s look at this situation from the rear of the car turning left.

The cornering force coming from the tires pushes on the suspension, and the suspension in turn pushes on the body. The place where the suspension pushes on the body is at the hinge axis that the body rotates around, which is the roll center.

The cornering force coming from the suspension is concentrated at the roll center, and because the body wants to keep going in a straight line, there is a reaction force at the center of gravity (CG). The difference in height between the roll center and the CG is the roll moment arm, which together with the body reaction force creates a roll moment, or torque, which causes the body to roll. The larger the roll moment arm, the larger the roll moment will be and the more the body will roll. The smaller the roll moment arm, the less the body will roll.

Imagine if we could raise the roll center so it was at the same height as the CG (or imagine if the Cg were super low). The roll moment arm would then be zero and there would be no body roll at all. Also imagine if the roll center were above the CG, then the body would roll in the opposite direction, like a motorboat.

Unfortunately, high roll centers cause issues that are impossible to fix, namely, jacking and harsh ride. These two videos explain why that is and why designers of independent suspensions are adamant about keeping roll centers relatively low:

High roll centers allow the wheels to tuck under the body when subjected to cornering forces, lifting, or “jacking” the body upward and reducing the stability of the car as happened with this Triumph:

High roll centers can also impact ride quality since the tire contact patches are forced to move closer and away from each other as the body moves up and down over road bumps. Since the tires just want to roll in the direction they are facing and don’t want to move side to side, they resist the smooth up and down motion of the body. Low roll centers reduce this side to side, or scrubbing, motion and allow the body to move more freely, resulting in a better and smoother ride.

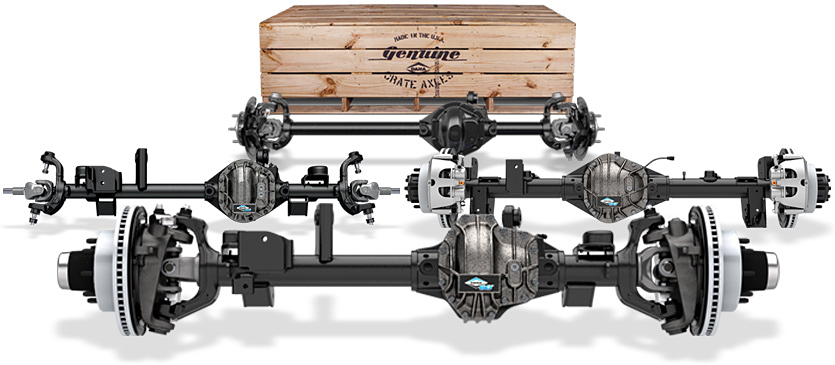

As it turns out, one way to get around the issue of jacking is to use a solid axle like one of the four shown above (by Dana), since the left and right suspensions are effectively rigidly connected to each other, and the tires cannot tuck under the body the way they can with an independent design. Solid axles also solve the ride issue since the tires cannot move closer or farther from each other. Of course, solid axles have their own ride issues caused by their heavy mass and the fact that the wheels cannot move independently. Like everything, it’s a tradeoff. The result is that with a solid axle, you can have much higher roll centers without the problems you would have with an independent design.

By now you’re probably wondering what all this has to do with the Jeep and Bronco comparison David wrote back in 2020. Remember that the Jeep has a solid front axle (shown above) while the Bronco has an independent front suspension (shown below)

This means the height of the front roll center in the Bronco will have to be much lower than in the Jeep to avoid jacking and ride problems. The roll moment arm in the Bronco will therefore be much larger than in the Jeep and the Bronco will roll much more in a turn. The only way to control this roll is to use a device such as an anti-roll bar. Sounds fine, right? Just about all vehicles have anti-roll bars in the front, and even some Jeeps have them so why should this be a problem? The problem is that the anti-roll bar in the Bronco will have to be much larger and stiffer than the one in the Jeep to compensate for the lower roll center and larger roll moment arm. The Bronco will need much more roll stiffness in the front suspension to keep body roll to an acceptable level. To understand why this is a problem, we need to understand something unique about off-roading.

Cross Articulation

Success in off-roading and rock crawling means keeping contact between all four tires and the ground as much as possible. When one wheel is lifted high up to get over a rock, you want the other three tires to remain in contact with the ground, so you have the traction needed to keep the vehicle moving forward. If one of the tires lifts up off the ground, you risk spinning that wheel and then you’re stuck. You could use locking differentials and all but you’ve still lost the traction of that tire and that’s not good.

The ability to keep all tires on the ground means having a lot of something called “cross articulation,” This refers to the ability of the axles to twist in opposite directions. It’s measured with a ramp as shown by this Jeep here and is measured with something called the Ramp Travel Index (RTI):

RTI is calculated by measuring how far up the ramp the front tire travels, dividing this by the wheelbase and multiplying the result by 1000. The higher the vehicle can drive up the ramp before one of the other tires leaves the ground, the higher the cross articulation of the axles and the higher the RTI. This can only be done if the axles have low roll stiffness. High roll stiffness, like we would have with a stiff anti-roll bar, means it is much harder for one wheel to move up while the other moves down.

Anti-Roll Bar Disconnect

The Bronco, with its stiff front anti-roll bar, would not do as well on a cross-articulation ramp as the Jeep would and would also not do as well crawling over rocks. Ford knew this, of course, but still chose to give the Bronco an independent front suspension. Independent suspensions give much better ride and handling on regular roads [Editor’s note: And they facilitate rack and pinion steering, which is more precise. -DT] and since most vehicles, even off-road vehicles, spend the majority of their life on regular roads, Ford decided it was more important to give the Bronco good on-road ride and handling rather than good rock crawling capabilities.

They weren’t worried, though. They knew there was a way around the high roll stiffness they would have to give the Bronco, and that was an anti-roll bar disconnect. An anti-roll bar disconnect is a device that effectively disconnects the anti-roll bar from the suspension, taking away its roll stiffness effect. It can be either electrically or hydraulically actuated but once activated, the anti-roll bar acts like it got cut into two pieces that can move independently from each other. You wouldn’t want to drive down a regular road with the front anti-roll bar disconnected, so these systems have a feature that, for safety, automatically re-connects the bar above some specified speed.

MotorTrend posted a good article back in 2021 comparing the RTI for the 2022 Ford Bronco with various Jeep Wranglers. The results show that while the Jeeps were still better than the Bronco for RTI, a stabar disconnect makes a huge difference in how far up the ramp a vehicle can travel. This Edmunds video doesn’t use an RTI ramp but instead a ziggurat, and it shows the same thing:

The reason why the Jeeps are still better for RTI is likely because of differences in available wheel travel and the stiffness of the springs. It’s pretty easy to design a solid axle to have lots of wheel travel. Independent suspensions have limits in how much angle the halfshaft CV joints can tolerate and how much articulation you can get out of the ball joints. Both of these limit how much travel you can design into an independent suspension. Without knowing the exact values for travel and spring rates for both vehicles it is difficult to know for sure, but once the stabars are disconnected, the only thing limiting RTI would be available wheel travel and spring stiffness.

Here’s a video of the folks at Lite Brite Nation taking a Jeep Wrangler and a couple Broncos through the Fawlty Towers trail in Utah over some seriously gnarly terrain:

The severity of the events is obvious when you look at how high off the ground the tires get:

Still, both the Jeep and the Broncos were able to get through all the events except for one which was more a test of break-over than articulation. One of the Broncos spit out the guts of a front CV joint (see below) in that event but that was related more to the lift kit installed rather than an inherent problem with the suspension.

Lift Kits

Speaking of lift kits, is there a difference between independent suspension and solid axles when it comes to lift-ability? There most definitely is. Most lift kits for independent suspensions use a cheap spacer placed at the top of the spring which pushes the entire spring/damper assembly down. This has the effect of pushing the vehicle up but in so doing changes the angles of all the control arms and the halfshafts. There are some kits out there that include new frame cross members and taller knuckles to fix the control arm angle problem, but these require changing a lot of your suspension parts and are much more expensive. Few of them solve the halfshaft problem though, and these can be quite serious. Here is an example of what happens when you lift an independent suspension vehicle too much. The halfshafts over-travel and spit their guts out on the trail:

Solid axles, on the other hand, can often be lifted with a simple set of blocks between the axles and the springs or by installing taller springs and a few suspension links. You need to keep an eye on the driveshaft angles, but they tend to be less of a problem because the shafts are longer, so a lift doesn’t change their angle as much. Plus, since the entire axle is lifted as a unit, the steering and outer joint angles don’t change. If you want to lift your off-road vehicle without using larger tires, solid axles are much easier and cheaper.

[Editor’s Note: I’d like to also mention that it’s a lot cheaper and easier to replace an axle’s u-joint than it is to replace an independent suspension’s CV joint. Seriously, here’s a u-joint replacement job:

CV joints tend to not get changed at all; instead, independent suspension-equipped vehicle drivers tend to just replace the rather expensive halfshaft like so:

I’ll also mention that I’ve had CV joint rubber boots crack, and once water gets into those cracks and dirties up/removes grease from the bearing surfaces, the joints fail quickly. U-joint seals have held up much better in my experience.

-DT].

The Ultimate Question

Now comes the ultimate question: which is better, solid axle or independent suspension? The answer, as you might expect, is “it depends.” If all you ever do is off-roading and rock crawling, then a solid axle would be my first choice. It’s cheap, rugged, and gets the job done. If you want to spend any time driving on regular roads, however, an independent suspension has vastly superior ride and handling. You can also rock crawl with an independent suspension, but it tends to require some extra hardware, which means extra cost and complexity.

The whole thing pivots around one argument: “Success in off-roading and rock crawling means keeping contact between all four tires and the ground as much as possible”. There’s a couple underlying assumptions to that that aren’t necessarily true. I can have a tire in contact with a surface but contributing jack-all to traction. Reality is… with modern computer controlled traction systems… this argument is not as strong as it once was. Look at videos of the newer Defender where it can climb obstacles that a LOT of offroaders would say “no way”. The argument is just not that cut and dry. Not anymore. Now…. the final argument: “if all you ever do is off-roading and rock crawling, then a solid axle would be my first choice. It’s cheap, rugged, and gets the job done.” The other factors play in. But…. most of us that go offroad don’t tow a vehicle to a spot solely for offroad. Ultimately…. it comes back to “what works best for what you intend to do?”

Civil here. All the same math but didn’t have a vehicle stability class. However I am the president of a 4wd club and have been wheeling jeeps for over a decade. Once you are outside of the “stock” 4×4 discussion and into typical lifted/modified rigs there are so many topics that I think deserve discussion by a suspension engineer. For example: how tippy 3 wheeling with stiff suspension is super easy to roll, differences between sway bar disconnects and soft “trail rate” sway bars in real wheeling (not RTI/CTI), how “bump steer” on rear parallel 4links impacts trail control compared to triangulated 4link, how brand loyalty makes the aftermarket adopt inferior design (radius arms vs 4 links, ball joints vs kingpins, closed knuckle vs ball joint, etc.).

Great content! As an add-on, I seem to remember from my automotive engineering days that there is another issue with increasing the roll center height to reduce the roll during turns. If the roll moment arm is zero, then there is no suspension travel in turns, and the front/rear roll stiffness distribution, a key aspect to tune understeer/oversteer is only determined by the tire stiffness. Thus, the vehicle behavior will be sensitive to mismatched tires and/or inflation.

I miss my mark 1 spitfire, terrible rear suspension and all.

I have been off roading for 30 years and have had IFS, twin traction beam, and solid front axle jeeps and trucks. I really prefer the solid axle for off roading because of the cost of lifts, durability and less expensive repairs and simplicity. Having driven crap built from the 1960s to current I am so use to bad road manners (i have owned 5 jeeps) that I do not miss the nicer road manners of IFS.

IFS can be as good or better than solid axle performance-wise but it will never do it at the same price level.

I know it’s not directly related to this but something I’ve wondered for a while, especially since I have speed bumps on the road outside my house and my car appears to behave differently depening on whether I’m leaving or coming home, is whether or not suspension needs to “warm up” before it works best.

We always hear about warming up engines and gearboxes before driving them hard, and warming up tyres to get best grip, but dampers etc. have oil and springs will have different spring rates depending upon temperature so should we also be trying to warm up suspensions somehow to get them to work optimally?

At least from my own experience, it definitely seems to provide a different, better feel.

Back when she was young, I’d autocross and open-track my Mustang. I always noticed on the way home how after the handling workout, she was just so much more, I dunno, loose and fluid-feeling, even just going down the road. It felt like there was a much more progressive response to inputs, biting more smoothly and predictably, as well as the tires and the chassis working better together.

Mind you, this is an SN95 Mustang with a chassis that basically comes from the 1978 Ford Fairmont, so perhaps anything leads to an improvement in handling… 😉

My shocks are aluminum bodied and my suspension is noticeably stiffer in the winter versus the summer. Shock fluid viscosity due to delta T is a real thing. I’ve even considered wrapping my shocks in the winter so they retain more heat.

Seems like a job for a De Dion tube

Not offroading (is that one word or two?), or drive in snow and ice (thank you coastal California), this isn’t something that comes up, but reading and learning, as well as the comments that follow, well, I’m getting the education I didn’t get until now. How’s that for a run on sentence?!

I enjoyed both the response from Jalop and the discussion above. They were both very informative.

Thank you, Huibert.

I’ve thought about doing a spring over on my Scout, but haven’t pulled the trigger yet.

You do realize that all levels of government spend an incredible amount of our money on these things called roads. Sure some of them are better driven on with a farm tractor, but really, how many? Do I need solid axles to deal with potholes at the mall? /s

Does this explain the tendency of solid axle Jeeps’ right-hand pull, subject to following road contours? I think so?

I’m not aware of this issue but it’s unlikely to be a roll center problem. It is more likely to be something in the steering geometry that is asymmetrical left to right.

My guess is cross camber. I had my suspension modified recently and the alignment shop told me they didn’t get in as much cross-camber as they wanted but it was neutral. As a result, they said, it would follow the crown of the road more, and it does. Its not bad though, it just means a slight steering input on most roads, but on roads without a pronounced crown or trails the neutralness pays dividends.

Make a portal axle housing the knuckle element of an IFS and tuck the diff up real high and you still won’t have to worry about the CV angles.

We’re also probably not that far from electric wheel motors being small and light enough that the unsprung weight impact will be minimal.

Unfortunately, you can’t get the diff too much higher because the engine is in the way. Move the engine up and the whole vehicle gets taller and more top heavy. Portal axles can fix some of the CV joint angle issues but they are expensive and as other commenters have noted, they add losses to the driveline.

For those of us in Mustang-land, there were similar debates (which may still be going on somewhere on the old boards for all I know) over IRS vs live rear axle, largely instigated by the sacrilegious-to-some 2000s Cobra models.

With a seemingly similar end point – if all you do with it is drag race, sure, you want the live rear axle setup, but for all the rest of us, IRS is probably the way to go. And Ford itself finally agreed in 2015.

Which is why in 2015 I finally bought a Mustang. With the new front suspension and the IRS, it was finally a modern car. I think the sales success of the car since then shows that a whole lot of people agree with me. I worked in the Mustang team for a few years when I was at Ford and I heard the same tired old argument that the drag racers absolutely had to have a solid axle but really, the serious racers were going to rebuild the car the way they wanted to anyway so what’s the point catering to them from the factory. It never made any sense to me.

I always assumed Mustang kept the solid axle so long largely due to cost savings for Ford.

I bought my Mustang in 2014 specifically because of the big changes coming in 2015. I drove several post-2015 Mustangs, and they all handle much better than mine. But, I’m never going to race my Mustang (drag or otherwise) and the handling quirks (or, as some may call them, flaws) of the live axle set up are the reason I wanted a pony car as a fun car in the first place. The only flaw I wish I could fix satisfactorily is axle hop.

I remember as a kid in the UK learning that Mustangs still had leaf springs and it blew my mind. I’d only seen them on farm trailers before.

How long ago was this? Mustangs ditched leaf springs in the 70’s.

Corvettes on the other hand used them until just a few years ago.

Is the portal gear design ala Hummer H1 the best of both worlds?

Other than expense, what are the downsides?

Im no suspensionologist, but I know some of the big issues with portals (aside from cost) is that they add a lot of driveline losses because of geartrain heat and they add a lot of lever arm to the hub mounting location and need to be heavily reinforced to make it work.

Downsides are more unsprung mass, more maintenance items/failure points, much wider track (if adding aftermarket). You’re also putting more strain on your steering and it changes your suspension geometry.

There are other upsides too besides ground clearance. You can add an additional gear reduction in the portals, which works the same way as lowering your final drive ratio and it reduces strain on other drivetrain components.

There are multiple companies entering the scene with bolt-on portals for popular modern day 4x4s and I’m insatiably curious to know how they affect handling. Would love to see a review or impressions article on here.

They do nothing to fix the angular range of travel the half shaft can sustain. So total wheel travel is still maintained, barring a track width change, but the corner now has it’s neutral HS position above the wheel centerline, effectively adding lift at the expense of sprung, partially-rotating mass, cost, complexity, losses, etc.

Something you didn’t touch on: Height adjustable suspension.

With solid axles when you give them a lift and keep the tire size the same the axles remain at the same height ground clearance wise.

With independent suspension all around and height adjustable suspension (like the air suspension found on the Land Rover LR-3) it actually increases your ground clearance in a practical matter.

For example, lets say there’s a 9″ tall rock in front of your rig that you can’t avoid and you have two vehicles. One with solid axles front and rear with height adjustable suspension, and one with independent suspension all around and height adjustable suspension as well. Both have 8″ of ground clearance in the regular driving mode, both can raise the body up 3″ higher via the flick of a switch. The solid axle rig is going to have to bash itself over the rock to get past it as the axles don’t go up, only the body does. Due to the independent suspension setup of the second rig provided the rock isn’t too wide it can pass harmlessly under the body and between the suspension without any scraping or bashing.

And on road being able to lower the body effectively reduces the CG and improves aerodynamics.

While I prefer solid axles for their simplicity, durability, reliability, and cost this winter with the massive amount of snow we got I found that my 94 Toyota was having ground clearance issues while a friend’s LR-3 that I drove had no such issues on the same road since I couldn’t raise, and it’s stock.

Ford should honestly make a new LR3 style bronco variant with independent suspension front and rear with height adjustable air suspension. If they sold it in a 2 door manual with decent paint options I’d have to get one.

The counterpoint to this is that the independant suspension clearance is variable, where the solid axle it’s more or less fixed. Let’s say you are crawling over that 8 inch rock and you side slip or some other reason forces one of the wheels to drop. With the ind. setup you are going to hit something as the suspension compresses, with the solid axle, you won’t. It’s one of the comforts I take in the 80 series that I can travel fast over rocky terrain because big up travel events aren’t going to be putting my oily bits any closer to the rocks, just the body.

Thank you for your input, I didn’t even consider that possibility.

That being said my main use for ground clearance is on roads and in the snow.

You are correct but you are also adding a lot of complexity and expense. It’s true though that lifting an IFS car nets you improved ground clearance down the center of the car while doing the same in a solid axle doesn’t.

I genuinely don’t think height adjustable air suspension adds much complexity nor much expense.

Combine the air suspension system with air lockers and other air driven accessories and it would be even more useful!

If only portal axles were cheap and readily available. I would love to slap a pair on my TJ.

Ehhhhh if you’re hitting stuff with your diff on a solid axle vehicle you most likely need to work on your tire placement. Plus unless you have a negative air chamber with your air suspension when you raise it up you also raise the spring rate, killing articulation.

That said, I do have a 4×4 with 4 wheel independent air suspension I’m looking forward to taking off road some this summer.

Eminently, not imminently, talented

I do enjoy the idea that someone’s talent is imminent, though.

“I’m not talented yet, but just you wait…”