Nobody ever said the auto industry’s transition to electrified and connected vehicles would be easy, and General Motors is feeling that sting right now—or is it smart by taking a more cautious approach to production? We’ll be talking about that today, as well as Mini’s Britishness, Nissan’s costs and Cummins’ plans for the future. Let’s make it happen.

GM’s Big EV Rollout Is Going Slower Than Expected

At the beginning of this year, it seemed like there were a ton of legacy automakers locked and loaded to take shots at Tesla’s share of the EV market. Now, as we approach the end of Q1, we realize that if that’s going to happen, it won’t overnight. Case in point: GM, which has an extremely promising forthcoming EV lineup, but is stalling at actually getting those cars on the road, the Wall Street Journal reports.

We’ve covered this issue before, with Cadillac Lyriq production specifically. But a few months later, the problem isn’t getting much better. Here’s what the WSJ had to say:

More than 15 months after GM began building the electric GMC Hummer pickup truck, the company has been making roughly a dozen a day, a figure far below initial targets for this point in the rollout, people familiar with the matter said. The Hummer has a wait list of more than 80,000 people. Some Hummers have been stuck at dealerships under a sales freeze since October, as GM investigated a potential problem with water seeping into the battery pack.

GM’s other high-profile new EV, the Cadillac Lyriq SUV, which it started selling almost a year ago, is also experiencing an unusually slow ramp-up. Through February, GM had sold roughly 1,000 Lyriqs since it began building them in March 2022. Comparatively, Tesla Inc. sold an estimated 252,000 Model Ys in the U.S. last year, according to research firm Motor Intelligence. The Lyriq is a direct competitor to the Tesla Model Y.

GM aims to produce 36,000 Lyriqs in the U.S. this year, 9% lower than its original target, partly because of a tighter-than-expected supply of battery cells, people familiar with the matter said.

Did you know the Lyriq started production in March of last year? I don’t think I’ve seen any of them on the road, come to think of it.

What’s happening here, exactly? Battery supply chain challenges, for one; it’s going to be a minute before all these Inflation Reduction Act-driven U.S. battery factories will be online. That, and quality control issues, plus the ever-difficult challenge of making software that doesn’t suck. But GM’s customers, many of whom are quite excited about these cars, are getting frustrated:

Brooklyn resident Jonathan Mason said he ordered a black Lyriq in September 2021, and emails from GM indicated that he would receive the SUV by the end of 2022. That time frame slipped, and his dealer told him last week that there is no set delivery date for Mr. Mason’s Lyriq.

“This has been a harrowing process,” said Mr. Mason, a 36-year-old who works in healthcare information-technology at a New York health system, and is the son of GM retirees.

(Also, good luck charging that thing in New York City, amigo. If you need tips on how to run a 100-foot extension cord out your window to slow-charge this thing when you manage to score street parking in front of your place, holler at me.)

Some of this is surprising news. I understand why a slower rollout makes sense for the Hummer EV or the Cadillac Celestiq, as those are higher-end niche vehicles that were always going to be relatively limited in production. But the Lyriq? That’s meant to be Cadillac’s EV volume-seller crossover, priced to compete in that $60,000-$80,000 luxury range. GM needs to get those out and soon. For what it’s worth, people whose opinions I trust say the Lyriq is extremely good. But that doesn’t matter if GM can’t put them in customers’ hands.

So that’s disappointing. On the other hand, I think GM’s eager to avoid the quality mishaps that are plaguing Ford right now, especially on the EV front. And it’s had plenty of its own headaches there with the various Chevy Bolt fires; I doubt it’s eager to see such problems spread across the board.

[Ed note: I’d just like to point out the shocking number of issues automakers have had with their initial EV offerings. VW’s ID.4s have been plagued with software issues, Toyota’s BZ4X has had some odd wheel-falling-off issues, ditto with Rivian, Chevy’s had the Bolt fire problems, Hyundai and Kia have had to issue a recall over potential rollaway issues associated with the electronic shifter, Ford’s F-150 Lightning production has stopped over battery concerns, and on and on. And while you might have expected issues on any new car, these early EVs are things automakers need to get right; it’s a critical moment for them to build trust in this new era. And right now, everyone’s screwing up. Random thought: Right now, cars that were designed by teams working remotely are hitting the market. I wonder if we’ll notice any difference in quality as a result of the change in the way cars are developed? -DT].

Nissan Works On Cost-Killing, Again

Winning the EV game means more than just quality control and software that doesn’t suck. It’s also about cost control. Like any new technology, EVs are expensive to make right now. That will hopefully change as battery supplies increase and costs go down, but for many automakers making this transition, it’s more about scale and R&D than actual money. For now.

Nissan is the latest big automaker to revise some of its strategy to focus on cost control for EVs, specifically cost parity with internal combustion engines and vehicles—and in this case that includes hybrid cars too.

I actually like this plan from Nissan a lot, if the company can pull it off: bring hybrid car prices in line with those of gasoline-powered cars by 2026. Here’s one of its execs talking to Reuters:

The Japanese automaker said it will use the same components across models to make electric powertrains – the assembly which propels a vehicle – smaller and lighter, and reduce development and production costs by 30% within three years versus 2019.

It will also use solid-state batteries with materials that are cheaper than those usually used, such as nickel and cobalt, Senior Vice President Toshihiro Hirai told reporters.

“Materials that don’t use such expensive precious metals are being developed, which will be a major factor in reducing costs,” Hirai said.

Good luck to Nissan here. But a few caveats: from everything I’ve heard, solid-state batteries are about a decade away from being anything worth a damn at all, let alone for mass production at scale. So that’s quite a thing to bank on, but given Nissan’s resources, maybe it can figure that technology out.

Also, Nissan: if you need to ruthlessly cut costs, I know a guy. But he may need a few things cleared up in his personal life before you send him to work.

Mini Stays British, For Now

Real talk: Brexit has not been great for what’s left of the British auto industry. Rather than deal with trade tariff uncertainty and rising costs for parts, the big international automakers and suppliers have largely just peaced out and taken production elsewhere. Ford cut a bunch of jobs in the UK last month and Nissan’s COO is also telling His Majesty’s Government to get off their asses and do something.

Electrification is making the situation worse; the UK doesn’t really have a local battery industry, certainly not at a scale that would serve the auto industry. And if you have to import everything it’s just not worth it. In fact, here’s a fascinating tidbit from that Quartz News blog I linked to above:

The Economist pointed out that the crankshaft in a Mini made by BMW has to cross the English Channel three times for various stages of its manufacture before it can be installed in a car in the UK. Manufacturing processes like this are becoming much more onerous post-Brexit.

Not great. But for now, at least, Mini’s Oxford plant will get a nice lifeline from parent company BMW, reports Automotive News:

The last time we saw British industry in such decline we at least got some great music out of it, but I don’t see that happening this time around.

Anyway, it’s great news for that Mini plant; BMW had already sent Mini EV production to China as part of its deal with the automaker Great Wall and the next-generation Countryman will be made exclusively in Germany.

So what does the future hold for this brand? It hasn’t been a great couple of years for smaller cars (in the U.S., anyway; Minis are still ubiquitous in other parts of the world) and the days of BMW using an efficient small-car brand to offset fuel economy and emissions from its SUVs and sport sedans are basically coming to an end. Modern BMW makes tons of smaller cars, EVs and hybrids now. It may just not need Mini anymore.

I could see BMW offloading Mini entirely to Great Wall or some other automaker, probably a Chinese one, and being done with it entirely. But as a two-time Mini owner who would love to go for round three, I’d be extremely sad to see that happen, as it’s hard to see a future in the U.S. if things go that way. Hopefully I’m wrong. It’s happened once or twice before.

Cummins—Yes, Cummins—Gets Into Electric And Alt-Fuel Power

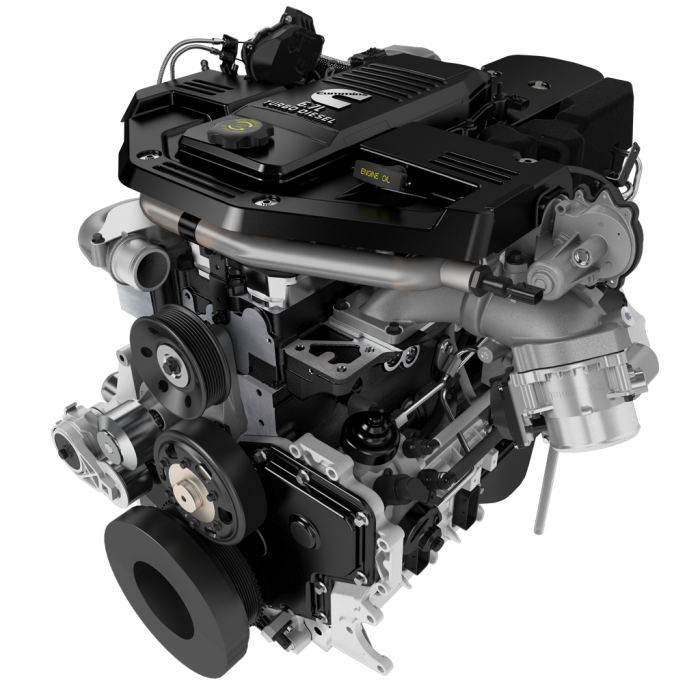

Speaking of The Future®: What do you do in the zero-emissions era when your company is basically synonymous with big, powerful diesel engines for trucks and industrial applications? [Ed Note: And also emissions solutions/exhaust aftertreatment. Cummins is elite in that area. -DT]. In the case of Cummins, you evolve or die. The company announced a big $1.5 billion investment into clean-energy technologies and a rebranding of the division to do it. One more from Reuters:

The U.S.-based engine maker announced on Wednesday it would change to name of its New Power division to Accelera and continue to offer battery electric and alternative fuel products such as engines, generators and power systems to meet its net-zero carbon emissions goal by 2050.

“We are actively evaluating the portfolio of what businesses we have. It is important to recognize that the core of our destination zero strategy is about zero emissions solutions and advanced solutions,” Chief Executive Jennifer Rumsey said in an interview.

The Columbus, Indiana-based company, known for its diesel and natural gas engines, has accelerated its push towards clean energy solutions to sell to its industrial and commercial transporation customers as the trucking industry is expected to face tougher greenhouse emissions regulations this year.

Accelera! Good for Cummins. There’s so much powertrain expertise in that company, it’s good to see it change with the times. They don’t want to become irrelevant and they’re doing well enough financially right now to start making these moves.

Your Turn

What’s the right course of action for automakers looking to make a big EV push? Get ’em out, or get ’em right? It’s a little maddening that GM can’t get the Lyriq into customer hands more than a year after production started, but I suppose that’s better than eating a ton of recall costs if quality isn’t where it should be yet. Are you concerned about these “early” EVs?

Support our mission of championing car culture by becoming an Official Autopian Member.

“(Also, good luck charging that thing in New York City, amigo. If you need tips on how to run a 100-foot extension cord out your window to slow-charge this thing when you manage to score street parking in front of your place, holler at me.)”

You do understand that all 5 boros of NYC have actual homes with driveways and or garages?

I have seen 1 Lyriq and it was on display in Dallas’ old-money mall.

Cars are already a difficult buy today. Costs are higher than they’ve ever been and automakers are more than willing to keep pumping the numbers because only a handful of people (statistically speaking) can do without one. Now tell the average consumer to spend an extra 10-20k on an electric version of the vehicle they already can barely afford.

I don’t have a solution because it seems like car companies don’t want to have one. Just add 6 more months to the 8% note and call it a day.

Legacy car manufacturers are are drooling over Tesla’s margins, and have concluded that building gimmicky iPhones on wheels is the way to get there. So they have to figure out all of that, *in addition to* switching over to electric propulsion. Hard indeed.

Renault Zoe and Nissan Leaf have been around for more than a decade, in large numbers. Relatively simple cars that their owners love, despite the lack of ot FRunKs and oVeR thE Air upDAtes.

Or silly door handles.

Its zero surprise the big 3’s issues with the EV transition, as they sucked at being good car companies before. Stellantis FCA who was behind the others was bailed out by the PSA merger as almost all their EV progress came from the PSA group, and they aren’t looking so bad as GM & Ford.

disruption usually comes from down-market up into higher value markets. that implies lower margin, higher volume EV products to start with. much mire difficult to move down market. but those entry level EV are lower margin, and the oems have made plain their disinterest in low margins.

alternately, up market products will have to compete with an established player, tesla, and a customer base perhaps less tolerant of hiccups.

none of that really matters with the status quo that they dont ship any EVs in volume.

if i were ceo (and there are many reasons i am not), i’d prefer the former: go entry level EVs and build the cadre of skills and infrastructure to then build on success and move up market. i also think a new organizational structure is probably required to succeed in EVs, so spin it off as a new brand with separate design, marketing and operations/manufacturing ( and think hard about building or buying batteries).

finally, there is still a very limited charging infrastructure, so that has to be addressed also. all while milking the ICE cash cow and investing in EV. the biggest challenge i see is how to get dealers on board with a new strategy – that’s the rock that could sink the canoe.

it might be useful to look for analogies in other industries that have already moved thru a transition like this (computers? telephones? pharma?) – are there any business professors out there? come on in, the water’s fine!

We’re running out of time for getting it right. Chasing Tesla and their “computer on wheels” philosophy is costing the industry time and money that could go elsewhere. Like developing lithium sources.

Skip the whiz-bang features. Give me a functional vehicle that happens to be electric. It doesn’t need to pretend to drive itself, badly. Adaptive cruise, blind spot monitoring and lane keep assist that works is the tech level that should be done. Those are mature systems at this point. And give me some buttons for controls I use regularly! Now get off my lawn!

Yeah, this, just do an electric car that’s just a normal car in every way except the propulsion method, getting batteries right is complicated enough as it is, no need to make things even harder on yourself for no reason.

And bring back physical controls and analog gauges, please

I think the wait to get it right or push and have recalls are 2 different issues. Of course, if you catch a problem, slow down and get it right but recalls are unforeseen. Manufacturing EV’s is a whole new game and issues are going to catch the makers off guard. It’s going to be super frustrating when someone waits an extra year for delivery and then six months later there’s a recall. It’s gonna happen.

I’d just like to point out the shocking number of issues automakers have had with their initial EV offerings.

I’d like to point out that Tesla is currently under investigation for the damned steering wheel coming off.

I’m not that concerned with the big manufacturers going slow and getting shit right considering how much is riding on them. Its not like Ford or GM has fanboys foaming at the mouth to dickride the CEO over their EV offerings.

Okay, all you folks that said “the big ‘real’ manufacturers are going to come on-line and crush Tesla”? Not happening.

Yup, that’s why Tesla has lost ~7% market share over the past year. Cause no one is coming for them. This is just starting.

:yawn:

Boring. Have a better argument?

We keep hearing it’s coming. Losing market share because the market is growing isn’t a bad thing at all. But there’s nobody close on profit per unit, and despite issues Tesla is *way* ahead in the software department. And they’re pretty much the most profitable carmaker per unit out there by a long shot. You know why Audi and Volvo won’t get in a price war with Tesla? They can’t afford to.

So yeah, bring it.

Lot of “GM in 1970” vibes from this post.

Broseph, there’s allllllll these issues with the big manufacturers, and Tesla still lost share.

Better software with shit hardware (cameras, lol) doesn’t mean anything.

Give it time. Year, maybe two. We’ll see what the status is then.

Hey Elon, shouldn’t you be posting this on Twitter?

It seems like the first mid-range BEVs are starting to arrive. Better equipped than the Leaf or other entry BEVs and with much better range.

Hyundai / KIA are rolling out a few models that I would expect to sell well. I’m not sure if they’re Tesla killers, but I’d take one over a Model 3 just for the slightly more ‘normal’ interior.

These new arrivals must be causing some sort of worry at Tesla, assuming they wouldn’t just drop their prices without reason.

Yeah, the interiors are a big selling point on not buying a Model 3. I want an instrument cluster in front of me. Speedometer, battery meter, headlight indicator, signal indicator, any alerts that come up, tire pressures…there’s a lot I prefer to have in front of me instead of on a center stack.

And that’s forgetting about the lack of physical controls for a lot of functions that should have them. A lot of manufacturers are relying a little too much on screens, but they still mostly have more physical controls than Teslas.

“What’s the right course of action for automakers looking to make a big EV push?”

Easy peasy…

See that 4-cylinder Honda Accord over there?? Just remove the motor, and put an electric one in, and that’s it. I don’t need ANY other change, software, driving assist feature, rear-view cameras, lane assist, automatic cruise control, etc…. All the stuff that is insisted on being included with an electric car, instead of JUST replacing the gas motor with an electric one, and a battery pack the same exact size of the gas tank, and fucking potentiometer attached to my accelerator pedal.

Decrease the cost by $1000 over (under?) the ICE cost (cause they are cheaper), and sell the living fuck out of them to everybody, including me, a person who has never bought a new car, but would if you offered this. And, no, Tesla can fuck off at this point. Give me a car made by someone who figured out how to make cars 50 years ago.

Seriously?

Instead of an LS swap, you’d do an “el-S” power train swap in an accord?

Might be a rather short (range 25 miles???) and very uncomfortable ride though without any heat, air conditioning, power steering, power brakes, traction control (other safety systems) and not to forget longevity without motor/battery coolant methods and any safe user friendly way of charging batteries jammed in the gas tank area. Oh all the entire weight distribution and suspension set up is completely compromised.

Hmm…

But at least the seats would be comfortable sitting on the side of the road waiting for a tow.

Yeah…it’s not that easy. If nothing else, just replacing the gas tank with a battery would leave you with unusably short range because of how much less energy density you get from batteries. AIUI, you’d end up with something like 20x less range, so your car that gets 400 miles per tank is now getting 20 per charge. That’s why full EVs make basically the entire undercarriage of the car the battery. It has to be that large or it won’t have any range.

“The Economist pointed out that the crankshaft in a Mini made by BMW has to cross the English Channel three times for various stages of its manufacture before it can be installed in a car in the UK. Manufacturing processes like this are becoming much more onerous post-Brexit.”

Imagine the carbon savings if they didn’t ship one crankshaft across the channel 3 times! We need to work to build things smarter!

There’s a lot of silly international shipping involved in industrial processes. Some shops have proprietary technology, some have less strict environmental laws, some are just located where labor and land are less expensive – more than offsetting the cost of shipping.

The UK is small. Getting parts from mainland Europe doesn’t involve more physical distance than a US factory purchasing parts from a US supplier in another state. It’s just that they went brexit with no real plan to continue this type of operation so now they have problems, and will continue to have them.

My wife and I are on our second Mach E. We traded the 2021 in for a 2022 with the larger battery. Aside from the new car eliminating our range anxiety, it also feels like it’s screwed together a little better than the first car, especially over bumps and around curves. The only major recall we went through was a windshield replacement. Otherwise, with the exception of the occasional software hiccups, we’ve been very happy with the car. New technology will always have growing pains; the intense focus on the EV car market by the media, government and Wall Street might have the cumulative effect of exacerbating people’s trepidation of making the jump.

“The only major recall we went through was a windshield replacement. Otherwise, with the exception of the occasional software hiccups, we’ve been very happy with the car.”

While I’m glad you are happy with your car, I think you being a little too forgiving. A recall to replace the windshield?!?? That’s not a new technology issue, that’s yet another Ford fuck-up production problem! Windshields have been included in cars for over 100 years now. A mediocre manufacturer should be able to get that right the first time.

I misspoke. The recall was for a faulty windshield seal on the first car. When they replaced the seal, they replaced the glass too, even though there was nothing wrong with it.

Color me dubious on getting the US auto industry electrified in a short period of time. Most of us recall the time needed for Tesla to be a real automobile manufacturer. And EVs are a complete redo of engineering expertise, not to mention logistics.

Then factor In charging out in the real world.

EVs will continue to be a status symbol for the next 10 years. If you really need a cost effective vehicle for anything other than short trips, it’s gas or hybrid.

Better hybrids would be a far more logical interim step than full EV.

Yep!

Automobile Econ 101:

Who makes cheapest and sells most wins?

I have certainly seen more Rivian Amazon Vans than either Hummers or Celestig’s

It’s been fascinating to watch the upswing of reservations and waiting lists for the hot new models. Maybe it’s always been that way for the truly cool new shit, but maybe going back to the “never buy a car in it’s year” is the way to go.

I agree. If I had the cash to drop on a new car RIGHT NOW, I’d much prefer finding the car on the lot than ordering/waiting/waiting/being driven crazy by waiting/waiting some more. But of course, I’m not some flibbety jibbet who has to have my way on everything, all the time, or my life is completely ruined.

I am some flibbety jibbet when I’m spending new car money. I used to be the sort who bought what was on the lot, but I want color. I want the options that I like. I’ll wait until the one I order comes in. I figure I’m already settling for the trims/colors/packages the manufacturer offers. I don’t want to further settle.

That said, I’m not going to pay markups or anything like that. I’ll wait. I don’t need it now.

*first year.

C’mon edit mode!

“In its year” isn’t technically wrong when in this day and age you better have a car reserved BEFORE it’s year if you actually want one. Ugh, that’s an awfully written comment.. hopefully it makes sense, I need caffeine.

I believe Detroit – Lightening is commenting on the fact that Autopian is 1 year old and still doesn’t have a functional comments section.

No edit mode

No way to sort by oldest or newest

No real threading of comments

No notifications that someone has replied to your comment with an easy way to get back to it and return a reply.

You know- basic things that are expected for a comment section on an automotive blog. Something that turn-key comment programs like Disqus do well.

I think a lot of the reservations are also driven by the fully refundable deposit model. I’m on a couple lists, but I figure I am low enough on each list to see how things play out and hopefully get a test drive in before I cancel/commit. It’s a relatively low-risk way to position yourself to get something if it turns out to be good.

The only real risk is if you dropped a deposit with a startup that might go under. Then you may be out a hundred bucks or so.

“And right now, everyone’s screwing up.”

Everyone except Volvo/Geely/Polestar, that is. No major issues with any of their EV offerings that I’m aware of. Sure, some minor stuff, but normal teething issues. No recalls or anything serious. They took a conservative path by starting with a proven ICE platform and electrifying it (Volvo C40, XC40 and Polestar 2). Then they started developing pure-EV designs (Polestar 3). And they haven’t tried to chase the super-cheap mass-market dragon. Granted their offerings are more expensive than many can afford, but it’s given them a solid foundation to build on. It’s a real conundrum when you’re shooting for the lower market offerings like Ford and Chevy typically service, but I still think that taking the time to get it right is better than getting them done quickly. There’s a small independent mechanic that I’ve used a few times who has a sign on their wall: “Do you want it done right, or right now?”

I have a Volvo C40, and it has had zero problems. The only knock is that Volvo is really slow to get software updates out for things that should have worked near day one; the Android OS models generally have things missing compared to the older Sensus UX. It’s little things like missing the driving log, to disabling the steering wheel switches that allowed changing cruise control modes. I’m hopeful that they will improve the functionality. PS Volvo, please enable the darn Pixel headlights!

They got their initial screwing up out of the way in 2020 when they recalled every Polestar 2 for buggy software and most for defective inverters.

Shoot, you’re right. Sorry about not remembering that. But I think I’m right about Volvo. They had a recall that involved their EVs and ICE cars for some brake-related issue.

I know that simple isn’t always easy, but a base model, low options vehicle with as few assists or tech as possible to meet new regs might be something that people would buy, especially if it had less wait time and fewer issues.

We have an EV in back in the shop after they replaced the battery under warranty, then it wouldn’t take the first recharge after we got it back. It’s been back in shop while they try to figure out the issue. No ETA on when we get our car back. Meanwhile my base model 2002 Tacoma continues to run well while it rusts into oblivion.

I’m not an expert and I’m probably stupid here but I have always thought that we should have been making our vehicles hybrids for 10+ years now. I have always thought that they’d make a ton of sense in rural areas like mine. Again, I’m an idiot but it seemed like if we had most of our vehicles in a hybrid setup that the battery tech would have been farther along? Maybe not. It just seems like BEVs are gonna take a much longer time getting out the door because of that as well as supply chain issues.

Yeah, we really let things snowball overall. Hybrids should have been the norm for 20 years, we should have had a lot of PHEVs for the last decade, and we wouldn’t be feeling so much pressure to convert to full EV right now AND we would be in better shape to do so.

Of course, even going full EV doesn’t solve the environmental issues. Private jets, shipping, industrial practices that rely on going to the least-regulated places, and so many other things need to be addressed. And we’re still going to be coming off the back foot on all of that, since most of it isn’t even really being addressed at all.

Back when the first hybrids hit the market 20+ years ago, my immediate thought was, yeah, this makes sense, all cars will probably be hybrids by 2010 or so. But, I was very wrong, they remained niche items, with the option only offered on certain models. Not really sure why, Toyota made a full size land yacht sedan that did 44mpg, I’d bet a hybrid Chrysler 300 or Dodge Charger could have gotten 40 or so

And I would LOVE a hybrid 300. Efficiency is the only reason I don’t have a 300 as my DD.

I think some of it is the Prius. It was an appliance. It was made a part of the culture wars. It was so far from getting people excited about driving that it made people wary of all hybrids for some time. I think it might have caught on more if Toyota had started with something like a hybrid Camry, so it couldn’t be an obvious symbol for some…if they had made it seem like a normal car with better gas mileage.

A big part of it too was gas prices not remaining at their 2008 highs for very long. Crash in 2009, brief spike around 2011, high-ish until 2014, then basically cratered until 2021. A lot tougher to make the case for a hybrid in those conditions.

That’s true. If our gas prices had been comparable to Europe’s during that period, I could definitely see more hybrids taking off here. Also, if light trucks weren’t a way to escape efficiency standards, I think we would have seen more efficient vehicles. Maybe not as big, or maybe just as big, but hybrids to meet standards.

Hell, what about the Challenger? Could you imagine something that still looked exactly like that, RWD, with performance at least comparable to the V6 version, that managed 40mpg? I’d buy one, hell, loads of people would buy one, it would be the perfect highway cruiser for long road trips, probably get 500 miles to a tank

Fair point. That would be a MASSIVE success and also something I would absolutely want to buy.

my 392 V8 with a manual trans gets 23-24 all day long on the freeway, closer to 20 around town. I am actually pretty amazed it can do that, but it is kind of like the early 2000’s corvettes getting 25 all day every day. lots of torque and Overdrive can net good fuel economy from a lot of things.

You’re right, and I just had a thing on that: https://heatmap.news/why-hybrid-cars-still-matter

People bought hybrids forever to save gas, but they also offer a ton of value in cutting down on emissions right now and bringing down battery costs. Maybe we’ll get to the point where more ICE cars are hybrid by default.

Yeah, I think it comes down to the narrative around hybrids being focused more on fuel economy for so long, not about emissions and pollution. Even for the OEMs it was more about what would hit the MPG targets. Toyota remained cautious on hybrid expansion for years after leading the charge (pun?). A hybrid Sienna would have done well long before it was finally introduced.

Eco-consciousness seemed to be more about reducing fuel production and usage and the amount of fuel used by big SUVs. Every review of a hybrid vehicle talked about the length of time to get the ROI on the premium of the hybrid from the fuel savings (plus the cost of battery replacement and its unknown longevity). If pollutants did come up, some loved to trot out that study or whatever it was that the production of a Prius was more harmful to the environment than a Hummer.

Diesels were gaining more acceptance and seemed like there weren’t any compromises – high mpg, no quirky hybrid drivability or styling or batteries. TDI Passats that were bigger than Camrys and better mileage than the hybrid? But we know how that played out…

Dude you’re not an idiot.

To OEMs making their first EVs at scale, get them out the door, don’t abandon the customers and learn something in the process. Consider it a learning experience rather than a money maker. Even the most ‘meh’ engineered EV is likely to make customers happy, for now. Then apply those lessons to the next generation of EVs.

I saw a Lyriq last week! I just happened to look out the window and one passed by my office. I realize as I type it, it has a air of “you wouldn’t know her, she goes to another school” but it’s true.

Not to detract from the EV quality issues and more to DT’s point about today’s new intros being pandemic era designs…I have been thinking about that lately, that cars of the current time are going to be comparatively iffy on quality, even the ones in production before the pandemic. The production/supply issues have meant everyone is trying to crank out what they can as fast as they can, yet things like feature availability are still a crapshoot. Honda just recently dropped blind-spot monitoring from several vehicle trim levels on different models.

Cybertrucks have been on order since 2019. Seems like an issue for even the best.

I don’t consider a car “for sale” until I see one on the lot that I can buy. Too many people willing to part with their money for a promise.

It is a bit from both columns. I want to see it right but the platform needs to get out there.

Nissans are meh cars, point A to B. These could work in rental or commercial fleets as they are leased or written off.

That will prove the tech, then better consumer models come along.

Accelera is such a good automotive-related name that I’m surprised it wasn’t taken (though it is close to Amtrak’s Acela).

Accelera is already the name of an industry standards group in the CAD (Computer Automated Design) industry, so I did a bit of a double take. There is also apparently a cloud solutions provider, a contract research organization, an Indonesian tire manufacturer, and a medical device provider with that name. I do have to wonder if there could be a conflict with the tire manufacturer trademark.

Get them right, I know for sure GM cut their development time compared to ICE vehicles, their timing is more aggressive. I have a reservation for a Blazer EV and its supposed to be available this summer. I don’t mind waiting another year but just get it right.

Recently I just swapped a Chevy Bolt due to the battery recall, GM used the whole MSRP of the car, even if I paid 12K less than that, to get a different vehicle. I got a regular Blazer for now and some money back

To be fair to Cadillac, they also struggle getting ICE cars into consumer’s hands. I’ve been on my Blackwing waitlist for 8 months now and no sign I’m any closer to the top than when I got my name in.

I was on the waitlist for 10 months for an Escalade before I gave up. Same for me, no indication that there was any progress; my order was stuck at the code for “received.” The holdups were supposedly Super Cruise (which was the main reason I went with an Escalade over something else) and the diesel engine. They were building Escalades without Super Cruise even though it was *standard equipment* and giving $50 rebates. (Funny, when it was an option it was a LOT more than $50). And they can’t get diesels from their own plants? What special parts do those need?

So then I read how “Ultra Cruise” is coming out on the EVs. Sure it is. They’ll be building 3 a day if they are waiting on that for each one.