“What the hell?!” I thought as I walked past Galpin Auto Sports, the best automotive modification facility in southern California (and part of The Autopian’s sister-company, Galpin). I stopped in my tracks and approached the new Cadillac CT6 sitting in the parking lot; its wheels had been replaced by pizza-thin ones made of plastic. “This can’t be one of those airless tweels meant to replace tires; it’s way too skinny. What’s the deal?” I walked into GAS to see if I could get to the bottom of it.

My initial thought was that these were temporary wheels used to store and move cars, and indeed, that’s exactly right.

A member of the GAS team pointed me to a Range Rover sitting in the shop. “You see this? This thing is on jack stands taking up precious room in our shop. Those wheels out there on that Cadillac help prevent this; they are just there to let us roll the car around easily.”

Apparently the Cadillac is having something done to its factory wheels; since this isn’t an uncommon job at GAS, there are often vehicles around the shop that have nothing filling their wheel-wells, stuck in place like beached whales. So that’s what these plastic wheels are for:

These particular ones are called JW-X22s, built by Italian company Jackwheels, who calls these things “universal wheel stands.” Note that they are not simply called wheels, because they’re in no way meant to be used on public streets (you’ll see the “not for road use” warning written directly on the wheel stand above). The wheel stands are “universal” because they feature slotted holes in their metal center hubs, allowing the Jackwheels to fit vehicles with various bolt patterns:

Here’s Jackwheel’s description of this peculiar looking device:

Jackwheels JW-X22 is a rim made of structural technopolymers, very light, equipped with a steel central hub, with a ring nut adaptable to practically eighty percent of the attachments and hubs of the cars in circulation and with an external anti-skid part as well, which therefore allows easy mounting on any car and obviously the possibility to move the car itself.

A practical solution that, thanks to the central hub with a series of slotted holes, to the special adaptation kit and to the instructions included in every single package of Jackwheels X22, it is possible to mount it easily and without any special equipment, on any type of car.

A great advantage for mechanics, body shops and any operator in the automotive industry.

Moreover, it is a device that is certainly valid and extremely advantageous also for the same manufacturers in the automotive sector, who often need to move cars on the line, when the wheels are still missing.

Or, even better, for the tire manufacturers who, not by chance, are thinking of offering it to the whole network of their sales and assistance points.

Here you can see how Jackwheels markets these things for tire shops, tow truck companies, and body shops:

Though the videos do show the vehicles being driven under their own power, GAS’s rep said it’s best to just roll these cars on these wheels, as these things are not meant to handle much skinny pedal. Jackwheels recommends a top speed of 5 mph, with a maximum load of about 2,200 pounds per wheel, each of which weighs only 19.4 pounds:

Check out that tread width: 60mm! To put that into context, my BMW i3’s absurdly skinny front tires are 155s, meaning they’re over 2.5 times wider than the Jackwheels!:

To give you an idea how skinny these are, here’s a look at the tread width relative to my hand:

Needless to say, these “universal wheel stands” look ridiculous when mounted to pretty much any car, though I quite like how, because of their lack of backspacing (i.e. lack of positive offset), they provide lots of access to the brakes and suspension parts normally tucked into the “dish” of a wheel

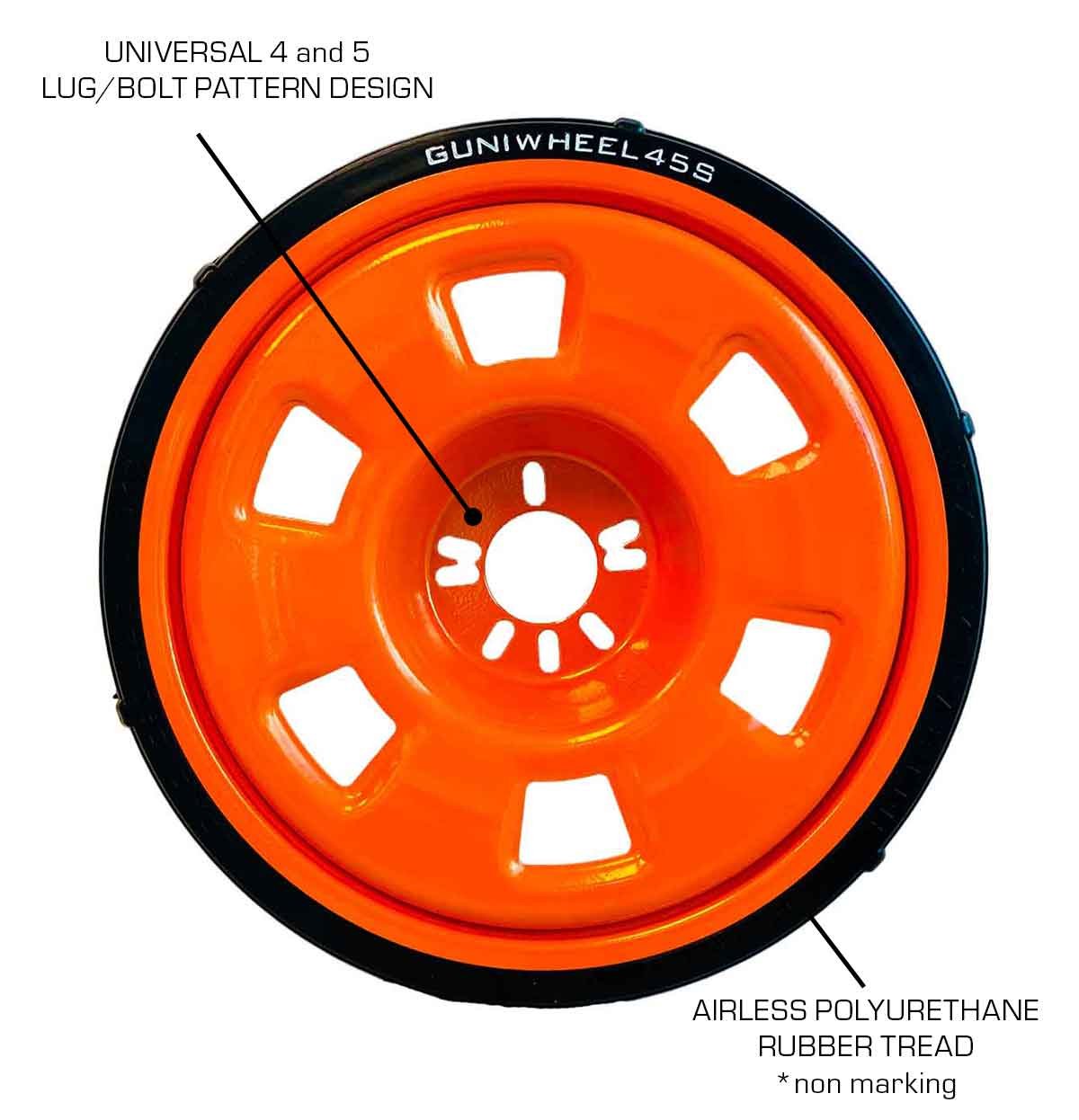

Jackwheels isn’t the only manufacturer who makes such devices, though their plastic design seems to be unique (note that I regularly use plastic ramps with seemingly-similar construction). Guniwheel is one of the big-dogs in this space, offering steel “shop wheels” (the design is also referred to as a “universal vehicle mounting system”) like this one:

“NO WHEELS? NO PROBLEM! SAFELY MOUNT & MOVE VEHICLES WITH OUR UNIVERSAL LUG PATTERN SHOP WHEELS,” writes Guniwheels on its website. Here you can see some of the features, including a speed-reducing hump on the 89mm wide tread (that’s significantly wider than Jackwheels’ 60mm wide tread):

Here’s a clip from Guniwheel’s website showing this ridiculous-looking “wheel” in action:

Anyway, I just saw that Cadillac outside of Galpin Auto Sports on my way home from work, and figured I’d share it all with you, dear readers. They’re basically lightweight, easy-to-stack/store methods of keeping cars somewhat mobile while their wheels are off for whatever reason. Hope you have a wonderful Sunday.

Images: Jackwheels, Guniwheel

I can see these wheels as being a great 24 Hours Of Lemons team punishment.

Those would be a LOT easier to use than jack stands for rotating tires at home.